The state of manufacturing data today could aptly be described as a paradox: paper producers have production data in abundant quantities. Yet it provides very little business insight.

This data comes in diverse types, formats, and collection frequencies, and is stored in different systems that don’t talk to each other. With such restrictive siloing, the various inputs cannot be scaled into a big picture of what’s happening throughout a production line… much less offer visibility into upstream variables that impact operations. Analytics can be applied only to minuscule use cases centered on just one or a small group of machines or processes. The answers are correspondingly limited in scope.

Sight Machine disrupts this dysfunctional status quo — by harnessing AI to stitch the various kinds of data together and then model a unified digital twin of the whole of production. Suddenly and often for the first time, paper manufacturing analytics gains the power to address and solve large, business-critical production questions and problems.

Let’s take a look at some examples within the three main areas of paper and tissue production.

Pulping Processes

To achieve both business and sustainability goals, intensive energy use needs to be reduced in all pulping phases and processes. Sight Machine digitally models the entire pulping plant, providing deep insights into the correlations between energy use and raw material mix, chemical mix, and process control input variables. Sophisticated paper manufacturing analytics are then applied to generate recommendations for specific process setup configurations to minimize energy use. Similar analytics can be applied to optimize water and chemical consumption.

The pulp of non-uniform quality can cause problems for both paper machine operations and paper end-product quality. By creating a digital twin of both pulping and papermaking processes, Sight Machine’s paper manufacturing analytics reveals correlations between paper quality and pulping process variables and then suggests remedies to deliver consistent pulp quality.

Paper Making

Uniform pulp quality goes a long way toward making the optimization of a paper, board or tissue machine a more manageable task. Even so, all paper making processes face a number of persistent and well-known obstacles in attempting to maximize overall equipment effectiveness (OEE). For example, grade changes are typically a drag on performance and quality, as changeover time is usually lengthy and results in an excessive cull. Through AI-powered analysis of historical runs, environmental inputs, and materials data, Sight Machine provides a solution in the form of recommended settings for the shortest grade-change time at the highest possible quality levels.

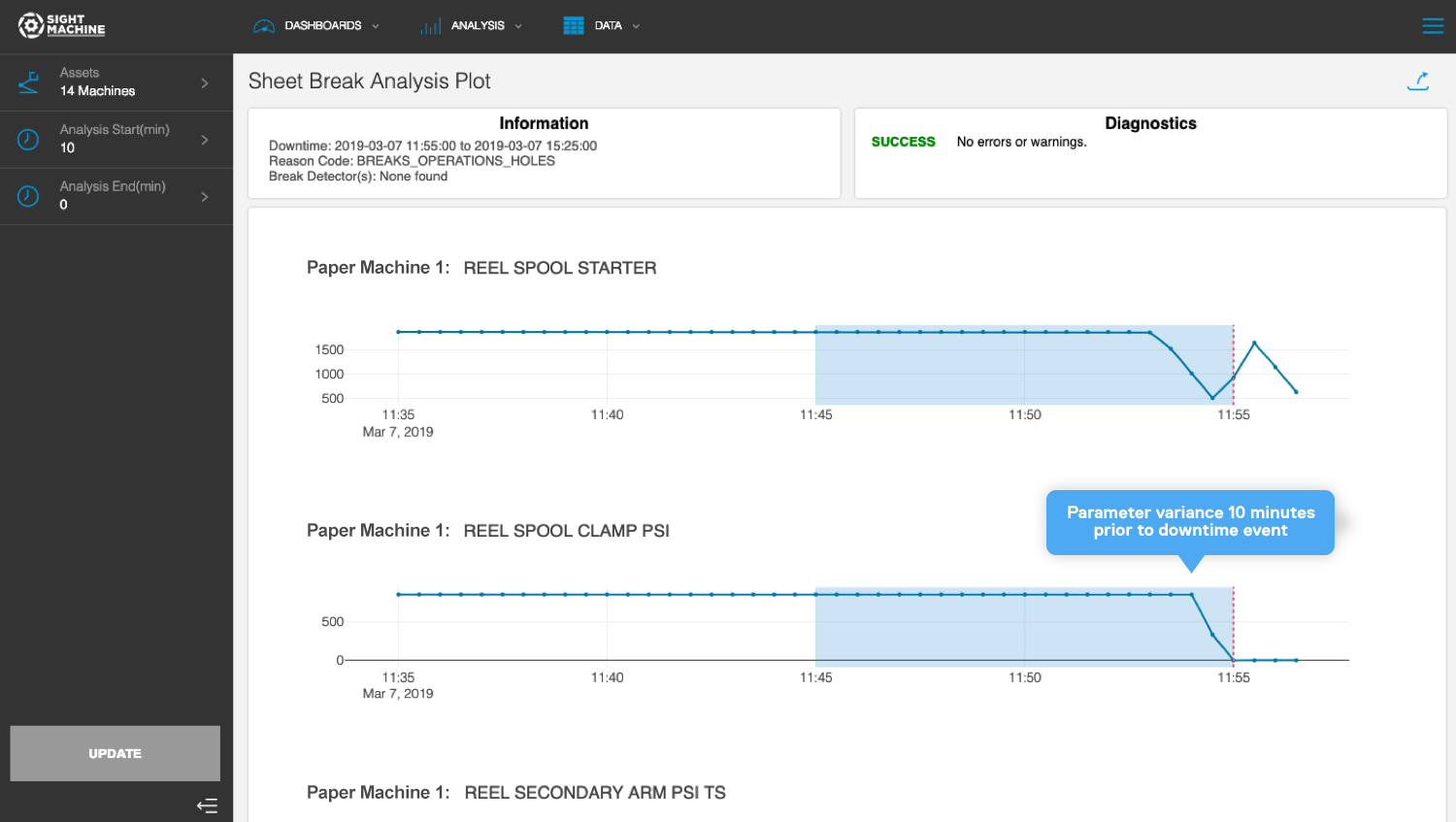

Production lines also often suffer from recurring web breaks, usually owing to a lack of insight into numerous causative variables. Most such breaks end up classified as “cause unknown.” Break data is sometimes manually examined afterward to search for contributing factors.

Sight Machine offers a more efficient and fruitful approach. Drawing on detailed models of production inputs and their complex interrelationships, Sight Machine algorithms assess recent sheet-break event data for the selected paper grade and rank parameters in order of variance prior to the disruption. Causation can then be determined and preventive action taken to prevent break recurrence. All this is done without the guesswork, manual data wrangling, or the need for arduous and time-consuming human analysis.

Another paper making challenge is an inability to efficiently and effectively troubleshoot the root causes of quality issues. Sight Machine overcomes this limitation as well, by correlating measured quality to relevant machine input variables, order information, and supply chain data. The Sight Machine platform presents relevant data in precisely the view, matrix, and context specified by the user. In effect, a few minutes of uncomplicated visual scrutiny reveals as much or more than laborious manual data pulls followed by days or weeks of numerical analysis.

Converting Plants

Converting plants for paper, board, and tissue is usually plagued by a lack of visibility into incoming product quality. This has several consequences. Runs are routinely delayed because machine parameters must be calibrated manually via inefficient trial-and-error iteration. Then, once a line is up and running, performance is often uneven and subject to unpredictable web breaks. If all this weren’t enough, consistent end-product quality is routinely challenging to achieve.

All end-product is typically treated as a match for quality specs, but in practice, this is often not the case, to the detriment of converting plant OEE. Line performance is frequently stepped down to avoid possible interruptions owing to various kinds of web defects. Quality issues also habitually arise due to variations in base product quality, such as those that affect digital printing on packaging grades.

Drawing on digital twin-enabled analysis of the upstream paper-making process, Sight Machine gives converting plant managers complete visibility into inbound material, delivering a range of improvements. Foreknowledge of the incoming product enables optimum converting line setup parameters to be learned and applied immediately upon product loading. These settings can be oriented toward producing the highest quality or generating the greatest possible output with minimally acceptable characteristics.

Sight Machine also provides advanced knowledge of incoming product attributes strongly correlated with process interruptions, allowing proactive line setup changes to be automatically programmed to avert disruptions. And, incoming material with known flawed characteristics can be rejected before loading or routed to lines specially calibrated to utilize it to generate an end-product of appropriate quality. Either alternative avoids fabricating, packaging, and delivering end-product that a customer may then reject.

Because converted end-product quality is usually not continuously measured, critical defects are sometimes discovered only belatedly, requiring large quantities of inventory to be scrapped or devalued. With its AI “finger” constantly on the pulse of all IoT streaming data, Sight Machine’s Paper Manufacturing Analytics can serve as an ongoing near-real-time quality sensor — constantly monitoring machines and processes, and intelligently alerting you to quality-related variances before significant amounts of under-grade product are created.

Finally, converting line operators typically have limited visibility into the causes of energy spikes during production. With energy monitoring equipment in place, Sight Machine can track and analyze streaming data on energy use together with other production variables. The platform will then correlate high energy usage with specific machine parameters and recommend setup values to minimize power consumption.